"Customers' demand for 2 nanometers is so strong that they can't even dream about it." In October last year, Taiwan Electric Chairman Wei Zhejia described the market situation exceeding expectations for the 2 nanometers to be produ...

"Customers' demand for 2 nanometers is so strong that they can't even dream about it." In October last year, Taiwan Electric Chairman Wei Zhejia described the market situation exceeding expectations for the 2 nanometers to be produced in the second half of this year.

Taiwan Electric will soon produce 2 nanometers in Hsinchu and Kaohsiung in the second half of the year. It is expected to drive the global end product value of about 73 trillion yuan in five years. It not only reveals the overture of the annual revenue of Taiwan Electric Power to watch 3 trillion yuan. This upgrade also allows Taiwan's factory to supply chains and lift horsepower, and upgrade five major families such as materials, equipment, factory/engineering, inspection, and advanced packaging.

At that time, the outside world believed and doubted because the market was worrying about whether AI was bubbled and how long would the semiconductor upcycle last? The price of 3 nanometer single wafer wafer has reached 20,000 US dollars, and the higher price is 2 nanometers. Do customers really buy the order?

In the following months, the 2nm progress message was silently interspersed among the tax issues related to Taiwan's electric-plus-code investment of US$100 billion and Trump's tax issues. Until mid-April, Su Zifeng, chairman of the US Ultramicro (AMD), rushed to Taiwan University to give a speech, revealing the 2nm hot scene.

"The new generation of ultramicro server processor, designated Venice, has completed 2-nanometer tape out." Su Zifeng happily expressed his cooperation milestone with NTU.

As soon as the first news came out, IC design factories such as Developer, Qualcomm, Microsoft, Meta, etc. were sold and followed by 2 nanometers, and are expected to be used in high-level products such as data centers, supercomputers, and mobile phones.

Plus, with the largest customer of advanced processing and 50% of the apple, it is expected that its 2-nanometer chip will be loaded with iPhone 18 and MacBook Pro laptops to be sold next year.

The first old customers and new friends who made the process went on a bus, and the demand for 2 nanometers was strong, and it really happened like a dream.

Taiwan's annual operating income reached NT$289.43 billion in 2024, compared with RMB 762.8 billion in 2014, and a 10-year growth of 2.79 times; gross profit margin also rose from 49.5% to 56.1%. In the first half of this year, Taiwan's electricity increased further, with a six-year increase of 1.773 billion yuan, an annual increase of about 40%.

Explore the main dynamic energy of the growth of the TECH, and complete the advanced process of day-to-point promotion every two years, which is very effective. This new process business that is huge and prosperous simultaneously drives supply chain technology upgrades and harvest growth.

"In fact, every time I enter a new process stage, the crystal factory will have changes in formulas, steps, etc., and the supplier will have small wheels. Therefore, the process changes and whether they can meet the needs of the crystal factory are keys to the suppliers who are on the rise." A supply chain veteran who has been working with Taiwan Electric for more than 30 years said.

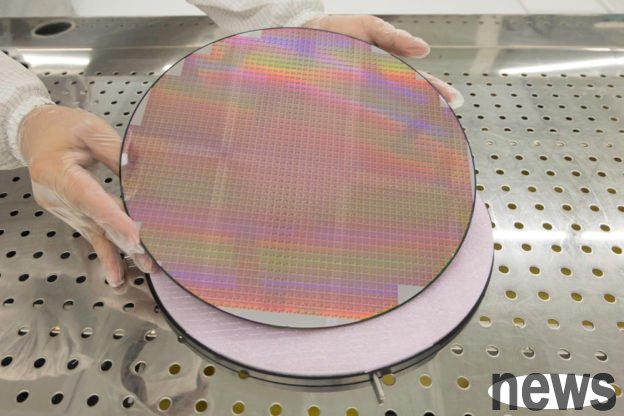

Supply chain observation, the 2nm manufacturing requires more time and steps than before, and it is more important to improve process efficiency. Moreover, the transistor is very small, and the cleanliness and equipment accuracy are more challenging. The formulation of various equipment and process materials must be adjusted accordingly. "The challenge is also where the merchant is located", and suppliers who enter 2nm say it at the same time.

For example, because of the increasing number of steps, the number of CMP (chemical mechanical grinding) layers is required to increase, increase the amount of diamond discs, and increase the medium sand; at the same time, the amount of regeneration crystal circles is increased, and the supply of Shengyang semiconductors, medium sand, and Xinyun are collected; consumables such as Home Container, which provides photocoat transmission boxes and Tianhong, which replaces zero-piece parts, are expected to increase.

For example, silicone that improves the process efficiency and helps increase the film deposition rate by 10 times will be supplied by Taitec; surface modification agents that prevent post-image photoresist graphic collapse are developed by Xinhui Materials.

In addition, under the higher requirements of 2 nanometer purification, Shihe's precision cleaning equipment and Hanchen's controllable ion implanter have become a small number of production equipment that can be entered into advanced processes.

Huajing Electric, Keno, and Creative Control, which are good at preventing and controlling micro-pollution, has helped to ensure the relevance of cleanliness, and has also changed in the inspection and analysis, automation, and system layout methods. It can be said that with the advancement of NTF's advanced production process, the entire 2nm supply chain machine has also been booming and is full of vitality.